You need a suitable container seal if you have nightmares about stolen or damaged cargo. In this blog, we’ll run through the different container seal types, which ones are the safest, and how to ensure you use them correctly to prevent theft and damage.

You receive your container at the port only to find that your goods have been tampered with, stolen, or broken. To make things worse, you have no proof, so you can’t claim from insurance. The solution? Picking a quality container seal protects your goods and acts as proof of tampering or seal reporting at the time of intrusion, not just when receiving goods.

- What is a container seal?

- Why use a container seal?

A container seal is a tag that secures the door lock of your “box”. Container seals are made to withstand harsh weather conditions and safeguard the container on its journey. Seals can be used for individual parcels as well. Package or particular unit identification and even location are relevant information for high value Each seal has a unique identification number, and traditional seals can only be broken once. After it’s been broken, it needs to be disposed of, as the owner can’t use it again. Electronic seals can be multiuse, and seals never get intentionally broken but open electronically.

There are many different types of container seals available. Choosing the proper seal will depend on your container type, the long route, and what you’ll be shipping. You will need a container seal if you don’t want your precious cargo stolen or messed up. Container seals keep your goods safe and secure inside. Not only this, but they also prevent criminals from planting contraband or illegal substances into your box, which can get you into much trouble.

If your container seal is broken upon arrival, this is a sign that your container has been intruded on. It’s also possible that goods may have been removed or damaged. The container seal proves that your box has been handled by someone else. With this broken seal as proof, you can claim damages and theft or report that items have been added to your container illegally. Container seals also protect your goods from harsh weather conditions, as they ensure the doors are closed tightly, preventing the elements from getting in. Conditional integrity with temperature, light, humidity, and environmental integrity expanding toward the goods’ position, while acceleration, shaking, and tremoring are secondary indications of the good’s handling. These are especially important with perishable goods such as food items, high-value products, and medicine. Indicators showing at the end of the journey will create benefits but not allow proactive actions or corrective actions for goods handlers.

Authorization Integrity is the most critical indicator. While electronic seals are opening and closing and need authorization, keep records of where, when, and by whom actions have been taken.

Vedia eSeal enables integrity and ensures location/position-based real-time information available.

Different types of container seal

Container seals come in many shapes and sizes and are made from various materials. Some commonly used container seals include:

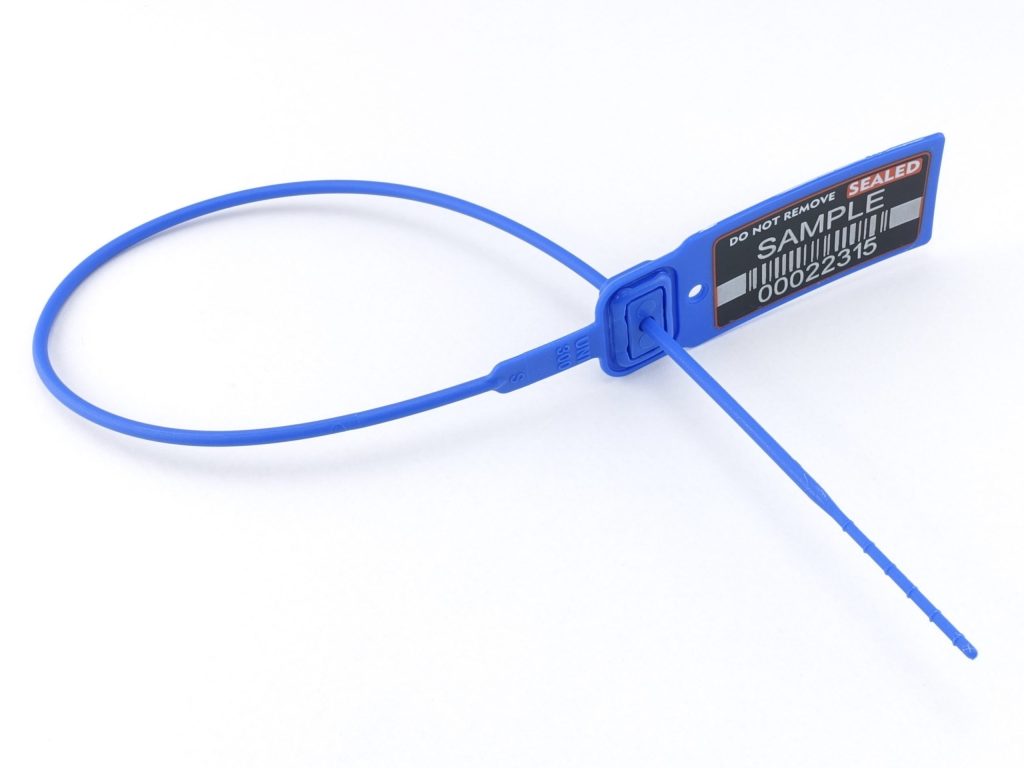

The plastic seal

These come in various colours and sizes. Plastic seals are perfect for short journeys and provide clear evidence of tampering. They can vary slightly depending on the manufacturer. As with all seals, a closed plastic seal can’t be opened without being cut. This seal is best for short journeys, as it’s not very strong and is easy to break.

The bolt seal

These are sturdier than plastic seals, so – you guessed it – they’re harder to break. Bolt seals are made of metal (usual steel) with a plastic casing. It would help if you had a bolt cutter to open a bolt seal. Because they’re made of metal, these seals are strong and provide excellent security for your boxes.

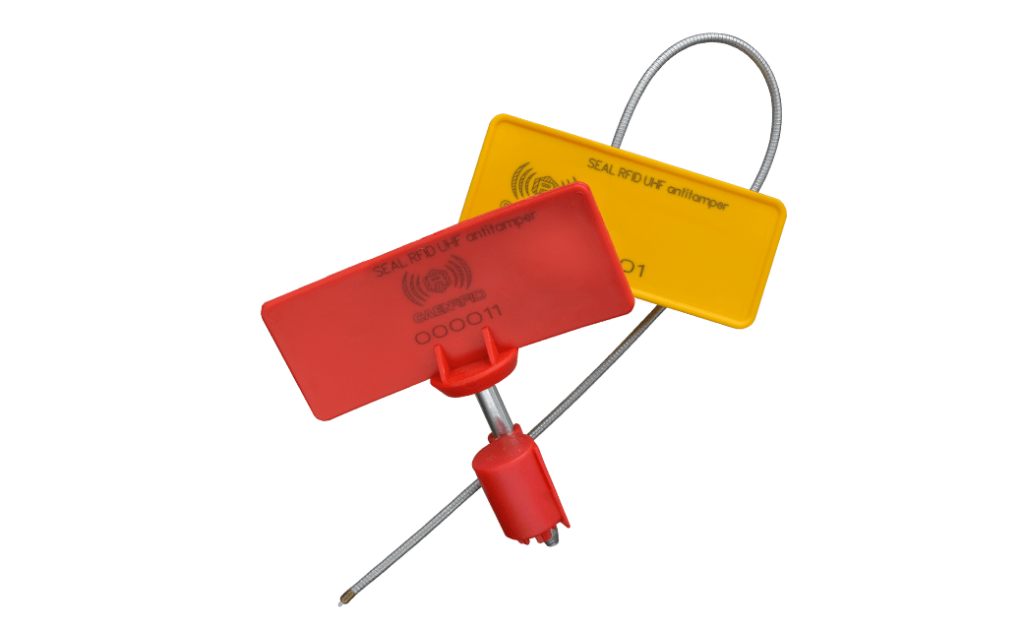

The RFID-seal

An e-seal looks just like a bolt seal but with the added benefit of RFID (Radio Frequency Identification) technology. It has a unique ID that can be scanned through a mobile reader. This seal speeds up the customs clearance process because it can be verified automatically. Now isn’t that convenient?

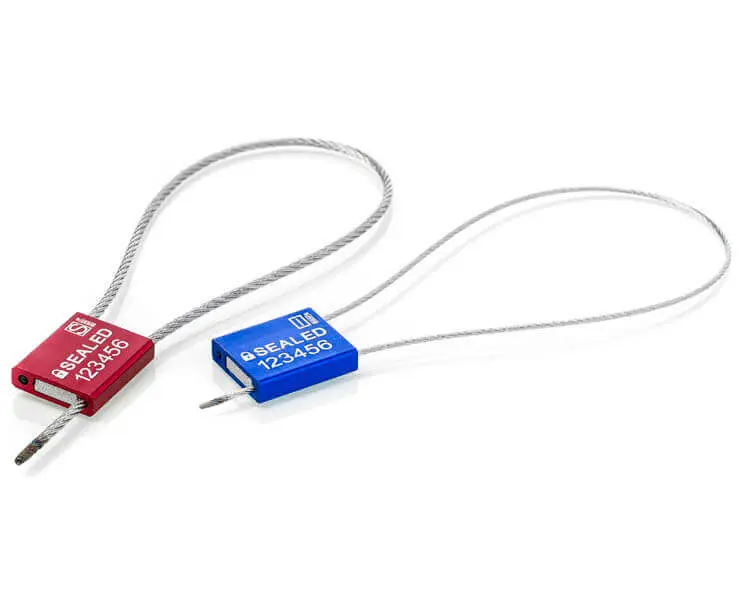

The cable seal with electronics

These seals have a steel cable and are self-locking. Cable seals are heavy-duty and, like bolt seals, can only be opened with a bolt cutter. However, they’re flexible and last longer than other seal types, even in unfavorable weather conditions. As a result, cable seals are the most popular container seals in the shipping industry. Easy to seal any position which is meant for locks, when electronics can be used to open, lock and reporting location with additional sensors for conditions of cargo. To be called eSeal.

The metal strip seal

These seals have a ball-shaped end and are self-locking. They’re made of metal that’s highly resistant to corrosion and damage. Metal seals can endure long journeys in all types of weather conditions and are used to secure various container types. Metal seal is passive. If broken violations can be recognized on checking, but not when and not from route.

Placing a container seal correctly: How and where to place it

A standard container has two doors, each with a lock rod for security. The lock rods have handles with holes through which a seal is attached to the container door. The left door of the container is generally closed first, followed by the right door. So, you will want to put the seal around any lock rod on the right door.

Container seal standards

Container seals are standardized by ISO 17712, which is recognized worldwide. These standards include the following regulations:

- A container seal must be a single-use device that is easy to inspect.

- Each seal must be unique, difficult to copy, and marked with basic information, such as

- the logo of the company and a unique identification number.

- Security bolt seals must be at least 18 mm in diameter.

- The tensile strength of a container seal must be greater than 1000 kg.

- The cutting strength of a container seal must be greater than 340 kg.

Port and customs requirements for container seals

You must have at least one container seal per shipping container in order to pass through customs. As the shipper, you’re free to add more seals if you want your box to be extra secure. The maximum number of seals you may have on your container is 6. The customs department can pick up your container for a random inspection. During an inspection, your seal is broken so that authorities can check your container and its contents. Once the inspection is finished, a customs seal will be placed on your box to keep your goods safe. If you see a customs seal, you know that your package has been checked by customs and has not been tampered with – so don’t panic!

How to remove a container seal correctly

You have to remove a container seal successfully. eSeals are easiest to open via Backoffice applications and eSeal can be re-used, without losing integrity information. Traditional seals needs to be cut with a bolt cutter along the length of the pin. Depending on the strength of the seal, it might take you a few tries to cut through it.

When removing a container seal, take note of the following:

- Before removing the seal, check it for wear and tear or signs of damage.

- The seal number should match the bill of lading number and other shipping documents. If there’s evidence of tampering, the seal should only be opened once the shipping line and insurance representatives are present.

- If you see a customs seal on your container, you know it’s been opened by customs representatives at the port.

With parcel or high value unit tracking can be done with eSeal, depending on tracking duration which eSeal to be used. Radio technologies can be utilized for unit entering or leaving to area/perimeter, not limited to container, but can perform unit or vehicle level.

Author:

Juha Karppinen

Sales Specialist

juha.karppinen(at)vedia.fi